Description

Watertech Presscontrol Evo-Variable Speed Controller

TRE-EVO XX XX

The Watertech Presscontrol Evo is a variable frequency drive controller. It is designed to vary the number of motor revolutions of the pump depending on the water withdrawal by the system in order to maintain constant pressure and flow. Presscontrol Evo allows the user to adjust the system pressure and the pump restart pressure. It also stops the pump in case of water shortage and protects it from dry running. Presscontrol Evo comes equipped with automatic restart in case of failure and an anti-jamming function. The features of this controller mean it’s extremely energy efficient. The Presscontrol Evo can be installed on above ground and submersible pumps.

Specifications:

| Model | Max Motor Size | Inlet/Outlet | Amps | Phase | Voltage | Input | Output |

| TRE-EVO MM 8.5 | 1.1 kW | 25mm | 8.5 | 1 | 230 | 1~ | 1~ |

| TRE-EVO MM 11 | 1.5 kW | 32mm | 11 | 1 | 230 | 1~ | 1~ |

| TRE-EVO MM 11 COM | 1.5 kW | 32mm | 11 | 1 | 230 | 1~ | 1~ |

| TRE-EVO MM 13 COM | 2.2 kW | 32mm | 13 | 1 | 230 | 1~ | 1~ |

| TRE-EVO MT 11 | 2.2 kW | 32mm | 13 | 1/3 | 230/400 | 1~ | 3~ |

| TRE-EVO TT 6 | 2.2 kW | 32mm | 6 | 3 | 400 | 3~ | 3~ |

| TRE-EVO TT 16 | 7.5 kW | 32mm | 16 | 3 | 400 | 3~ | 3~ |

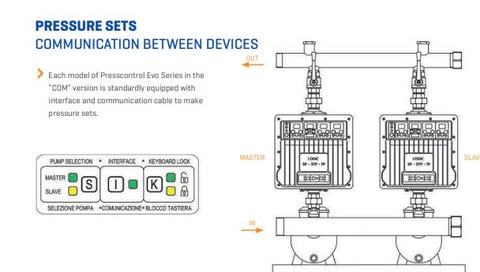

Com Models:

Communication between devices, allowing you to connect more than one to pump.

Features:

* High Quality Italian Design and Manufacturing

* Six Options Available

* Variable Speed

* A user-friendly interface with LED indicators displaying power status, pump running and alarm indication.

* Detailed control board which shows user – Amp current, pressure, system pressure and cut in pressure

* Single & Three Phase

* Anti Jamming Function

Technical Features:

* Frequency: 50 / 60 Hz

* Adjustable system pressure 2- 12 Bar

* Adjustable cut-in pressure 1- 11 Bar

* Maximum operating temperature -60 °C

* Maximum Bar Pressure-16 Bar

* Minimum Flow Rate- 1 lpm

* IP65

Automatic Restart & Anti-Jamming Function:

In case of stopping due to a water shortage, the device will automatically make 10 double attempts to rearm over the 24 hours following the failure, each lasting approximately 5 seconds to allow, if possible, the pump and the system to reload. The user can try to rearm the device at any time by pressing the Restart button. If for any reason the pump remains idle for 24 consecutive hours, the device will carry.

Installation & Start Up

Install the device in vertical position directly on the pump or between the pump and the first tap. Make all electrical connections, give power and wait a few seconds. When the set-up is completed the factory-set current and pressure values will appear on the display (CURRENT 1,5 A - SYSTEM PRESSURE 3,0 bar - CUT-IN PRESSURE 1,5 bar), the Current display starts blinking and the real pressure value of the system appears on the Pressure display. Set the current absorbed by the motor indicated on its nameplate. In order to adapt the system to the desired operation, it may be necessary to set different pressure values from those set by the factory: system pressure 3 bar - cut-in pressure 1,5 bar. Once the values are set, press the button ON (green LED on) to start. When the pump is running, the real value of the current absorbed by the motor appears on the Current display. In the event of a temporary blackout, the device automatically resets itself when electricity returns.

For more information see brochure below (pages 8-13)

2 Year Warranty

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.